|

Making Soap:

During the Civil War, women made their own soap. Sometimes

soap could be purchased at the general store, but many women preferred making their own. Land was cleared

by chopping trees, pulling stumps, and burning bushes. The ashes left from these burnings were placed in a barrel called

a "leach". The leach was put on top of a board and raised at one end. The bottom of the barrell had a slit in

it where water could seep through, and a bucket was placed under the slit. As water passed throgh the ashes, it trickled out

the slit as lye. It took quite a long time for the first few drops of lye to drip through to the bottom of the barrel,

sometimes an entire day. Lye was very dangerous to work with and could burn the skin very badly. As well, the throat

could be burned if the fumes were inhaled.

The next step was to boil animal fat and water into tallow.

The lye was then added to the tallow, and the tallow took away the strength of the lye. Then, depending on what batch

of soap the pioneer was making, other ingredients were added to the boiling lye-tallow mixture. For bath soap, bayberry,

lavender, or oats were added. For laundry soap, ammonia and borax were added. Finally, the liquid soap was

poured into a pan or box to harden overnight, and it was cut into bars the following day.

| Making Soap |

|

Carding Wool and Spinning:

During the 19th century, wool was (as it is today) an intrical and important commodity for people.

Naturally, it was used to make clothes, blankets, sweaters, mittens, etc. In some parts of the country, woolen goods

were available in stores, but in the Westand in the South, people had to make their woolen products from scratch. Queen

Victorian considered spinning wool into yarn as a sort of relaxing pasttime.

Creating wool cloth was a lot of work, and it took a lot of time as well. First, the sheep would be

sheared--removing all the fleece into a heap. The heap of fleece would then be washed and combed to remove dirt, burrs,

and twigs. This was done by placing the fleece between two carding paddles and pulling it through the paddles again

and again, called Carding Wool. It cleaned the fleece and also fluffed the fleece so that its fibers were ready to be

spun into soft yarn. The wool was spun into yarn on a spinning wheel, then it was dyed outdoors in huge iron pots.

The dyes which were used were made from berries or bark, and even

some vegetable such as onions! Once dyed, the yarn was then woven into cloth on a loom.

| Carding Wool |

|

| Spinning Wheel |

|

Sewing:

Clothes were primarily made at home, so there was always some sewing project going on. If it was not

time to be making new clothes, then there were always exisiting clothes that need repairs, or some darning that needed to

be done.

Besides darning, knitting, and sewing, women often crocheted, cross-stitched, and sewed needlepoint as decorative

doilies, table-runners, sachets, shawls, and reticules. A lady's needlework was often considered a refinement and that the

lady was of good-breeding and well-mannered.

| Sewing Clothes |

|

Making Candles:

There were no lights in a house, of course, but the fireplace

did provide some light in the evenings, and women also made their own candles. This was an important and necessary

task, but a chore that most children hated. It was messy and took a great deal of patience.

Candles were made by dipping pieces of loosely spun hemp into saltpeter and twisting them. Then

the hemp was doubled, leaving a loop at one end. These pieces of string served as wicks for the candles. (Later,

ready-made candles could be bought at the general store.)

The candle rod was slipped through the loops of ten or twenty wicks. Several rods filled with hanging

wicks were then lowered into the hot wax, rod by rod. It was typically the children's job to dip the wicks, then take

them out to dry and dip the next set, and so on. It would take many dippings to get the candles thick enough to last

for even one evening!

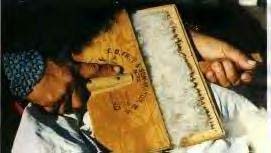

Another method of making candles was to pour hot tallow (grease) into wooden molds.

The molds were made of tin or pewter, and they were set in a frame. Some of the frames held as many as 100 candle molds.

Once the molds were cooled, the candles were lifted out by removing the top of the mold. The wax used

for their candles came from animal (hog) and vegetable (corn) fat. Bayberries and beeswax were also used in

making candles. Sometimes moose fat and bear oil was used. Boiling the fat in water until the water boiled away

and the dirt was skimmed off made candle wax. When homemade candles were burned, they smelled similar to frying grease,

but when they were made from bayberries, the fragrance was much more enjoyable.

| Hand-dipped Candles |

|

Canning Preserves:

Women usually began canning preserves for the wintertime once the first summer and fall crops began to come

into harvest. Women often took fruits and vegetables, blanched them in hot water, cooked them with sugar, salt, seasonings, or

vinegar (whether they were making fruit jams, vegetable cans, or pickled items) and filled Mason jars (invented in the

later 1840's) with the preserve.

Jars were first boiled for sterilization before being filled and boiled again to seal. If jars were

not heated to a high enough temperature, botulism, a deadly bacteria could grow in the jar and be accidentally consumed.

Meats were sometimes pickled, but were usually smoked and seasoned in a smoke house, left to dry out

to become jerky and other dried meats.

| Mason Jars for Canning |

|

|